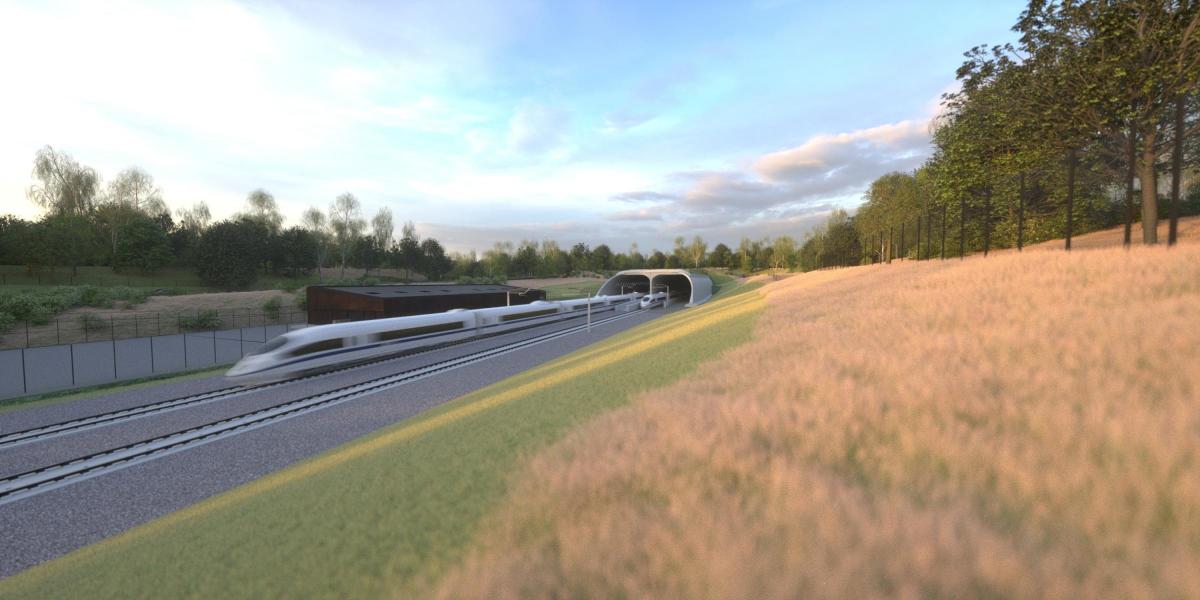

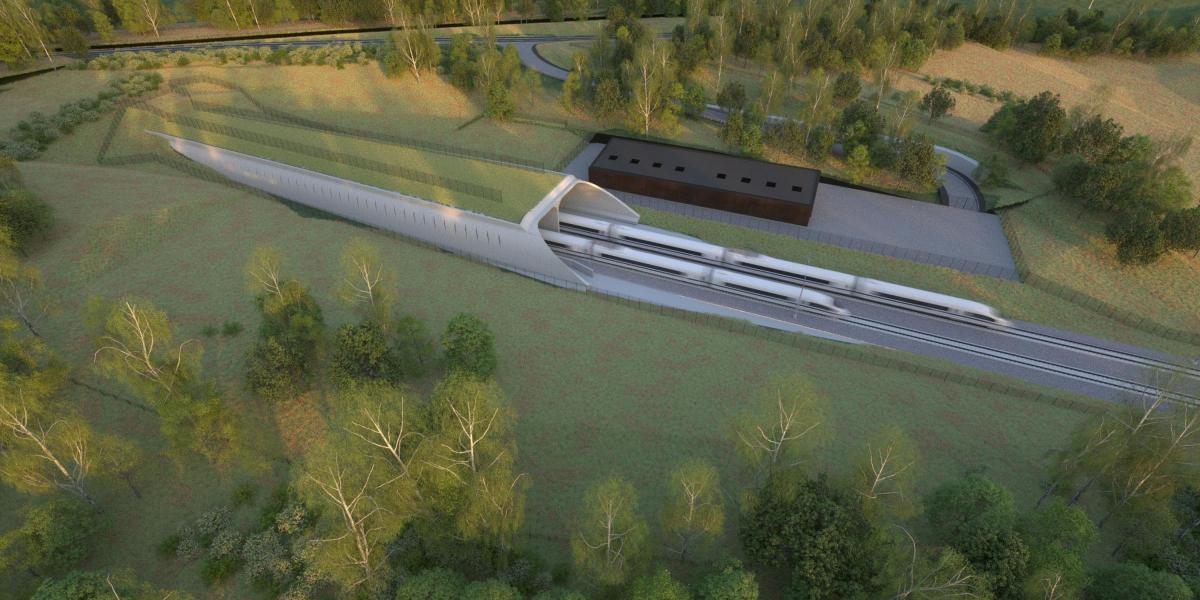

HS2 has revealed the first images of the longest of three ‘green tunnels’ that will be built across Buckinghamshire and Northamptonshire to help “blend” the controversial new high-speed rail line into the landscape and “reduce disruption” for residents.

New images show the green tunnel at Greatworth in Northamptonshire - and similar designs are planned for Wendover.

The one-and-a half-mile long Greatworth tunnel will be built in a factory in Derbyshire before being shipped to site and assembled over the railway line as it passes the village.

It will then be covered with earth and landscaped to try and make it fit into the surrounding countryside.

Designed as an ‘m’ shaped double arch, the tunnel will have two separate halves for southbound and northbound trains.

Instead of the whole tunnel being cast on site, five different concrete precast segments will be slotted together to achieve the double arch - one central pier, two side walls and two roof slabs. All 5,400 segments installed at Greatworth will be steel reinforced, with the largest weighing up to 43 tonnes.

HS2 Ltd’s Project Client Rohan Perin, said: “The Greatworth green tunnel is a great example of what we’re doing to blend the new railway into the landscape and protect communities living close to the line.

“By adopting an ‘off site’ approach to manufacturing, we’re also cutting embedded carbon from the design, improving efficiency, safety and making the whole construction process less disruptive for the community.”

Similar structures will also be built near Wendover and Chipping Warden in Northamptonshire, stretching for a combined total of four miles.

The tunnels will all have specially designed ‘porous portals’ at either end to reduce the noise of trains entering and exiting the tunnel and small portal buildings to house safety and electrical equipment.

Thousands of tonnes of rock and earth will be excavated during the initial stages of construction which will be stockpiled for reuse later on.

All 13,290 segments for the three tunnels are being made by Derbyshire-based Stanton Precast Ltd, in a deal which has created almost 100 jobs at their Ilkeston factory.

Andy Swift, delivery director at EKFB, HS2’s main works contractor team, made up of Eiffage, Kier, Ferrovial Construction and BAM Nuttall, said: “The green tunnel design is a combination of innovation, international engineering expertise and thoughtful landscaping for its local communities to enjoy.

“Once the tunnels have been built, the original earth removed from the cutting to make way for the tunnel, will be repositioned, creating a green space which will blend into the surrounding landscape.”

Comments: Our rules

We want our comments to be a lively and valuable part of our community - a place where readers can debate and engage with the most important local issues. The ability to comment on our stories is a privilege, not a right, however, and that privilege may be withdrawn if it is abused or misused.

Please report any comments that break our rules.

Read the rules hereLast Updated:

Report this comment Cancel